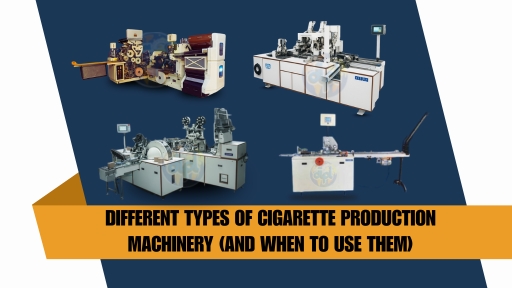

In today’s competitive tobacco industry, choosing the right cigarette making machinery is essential for maintaining quality, speed, and cost efficiency. Whether you are starting a new production unit or upgrading an existing line, understanding the different types of industrial production machines can help you make smarter investment decisions.

At Dynamic Tools, manufacturers can find reliable and customized cigarette machines designed to meet varying production needs — from small-scale operations to high-speed industrial setups.

In this blog, we will explore the different types of cigarette production machinery and explain when each should be used.

1. Cigarette Making Machines

The core of any tobacco production facility is the cigarette making machine. This equipment is responsible for converting processed tobacco and filter rods into finished cigarettes.

When to Use:

- When setting up a new cigarette manufacturing plant

- When increasing production capacity

- When upgrading to high-speed automated systems

Modern cigarette making machinery ensures consistent weight, proper filter attachment, and uniform rod formation. Advanced models come with automation features that reduce human intervention and improve production efficiency.

High-speed industrial production machines are ideal for large manufacturers aiming for mass production, while medium-speed machines suit growing businesses that need scalability.

2. Filter Assembling Machines

Filters play a vital role in cigarette production. Filter assembling machines combine acetate filter rods with cigarette rods accurately and efficiently.

When to Use:

- When you need precision in filter attachment

- When expanding production lines

- When aiming for better product consistency

Using specialized filter assembling equipment ensures uniform size and strong bonding between the tobacco rod and filter, which improves product quality and reduces rejection rates.

3. Cigarette Packing Machines

Once cigarettes are produced, the next stage is packaging. Packing machines handle bundling, wrapping, and sealing operations.

Types of Packing Machines:

- Shell and Slide Packing Machines

- Wrapper and Over-Wrapper Machines

- Boxer Machines

- Tax Stamping Machines

When to Use:

- When automating packaging lines

- When targeting export standards

- When increasing production speed

High-quality packing machines maintain packaging accuracy while preserving product freshness. For businesses planning to expand globally, automated packing systems help meet international quality and compliance standards.

4. Shell and Slide Machines

Shell and slide packaging is one of the most popular cigarette packaging formats. These machines assemble inner slides and outer shells with precision.

When to Use:

- When producing premium cigarette brands

- When requiring durable and structured packaging

- When targeting markets that prefer slide-style packs

Shell and slide machines are ideal for manufacturers focusing on premium positioning. They ensure smooth sliding mechanisms and consistent pack finishing.

5. Over-Wrapping Machines

Over-wrapping machines apply transparent film around the cigarette pack to protect it from moisture and damage.

When to Use:

- For enhancing product presentation

- For improving shelf life

- For maintaining tamper-proof packaging

These industrial production machines are especially useful in humid climates where packaging protection is essential.

6. Tax Stamping Machines

Compliance is a major factor in cigarette manufacturing. Tax stamping machines apply official tax stamps to each pack as per government regulations.

When to Use:

- When operating in regulated markets

- When exporting to countries requiring tax authentication

- When automating compliance processes

Automated stamping reduces errors and ensures that all packs meet legal standards.

7. Spare Parts and Maintenance Equipment

No production line can function efficiently without high-quality spare parts and maintenance systems. Precision spare components help reduce downtime and maintain machine performance.

When to Use:

- During routine maintenance

- When upgrading machine components

- When reducing breakdown risks

Reliable suppliers like Dynamic Tools provide essential spare parts to keep production lines running smoothly.

Choosing the Right Machine for Your Production Needs

Selecting the right cigarette production machinery depends on several factors:

1. Production Capacity

If your goal is mass production, high-speed industrial production machines are the best choice. For small or medium-scale operations, mid-speed or modular machines offer flexibility.

2. Budget Considerations

Automated systems require higher initial investment but provide long-term cost savings through efficiency and reduced labor costs.

3. Customization Requirements

Many manufacturers need customized cigarette machines tailored to specific packaging styles, production speeds, or regional compliance standards. Custom-built solutions ensure better integration with existing systems.

4. Market Demand

Premium markets may require shell and slide packaging, while other markets may prefer standard flip-top designs. Machine selection should align with target customer preferences.

Benefits of Modern Cigarette Production Machinery

Investing in advanced cigarette production equipment offers multiple advantages:

- Improved production efficiency

- Consistent product quality

- Reduced material wastage

- Lower operational costs

- Faster packaging processes

- Enhanced regulatory compliance

Automation also minimizes manual errors and increases overall plant safety.

Why Choose Dynamic Tools?

Dynamic Tools is a trusted provider of cigarette manufacturing equipment and industrial solutions. The company specializes in delivering high-performance cigarette making machinery, packing systems, and customized production setups designed for long-term reliability.

With a focus on quality engineering, precision manufacturing, and customer support, Dynamic Tools helps businesses streamline operations and achieve scalable growth.

Whether you are launching a new facility or upgrading an existing one, investing in the right industrial production machines ensures efficiency, compliance, and consistent output.

Conclusion

Understanding the different types of cigarette production machinery is essential for making informed decisions. From cigarette making units and filter assemblers to shell and slide packers, each machine plays a specific role in the production line.

Choosing the right combination of equipment at the right time can significantly improve productivity and profitability. With expert guidance and reliable solutions from Dynamic Tools, manufacturers can build efficient, future-ready production systems that meet modern industry demands.

If you are planning to upgrade your cigarette manufacturing line, now is the perfect time to explore advanced, customized solutions that match your production goals.