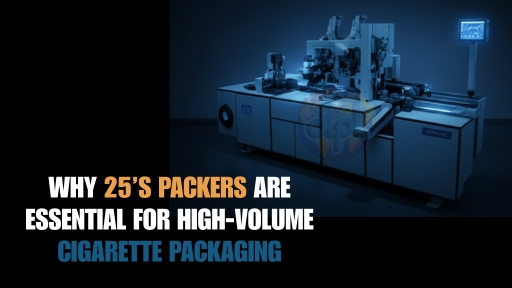

In today’s fast-paced tobacco manufacturing industry, efficiency, consistency, and speed are critical to staying competitive. As cigarette brands scale up production to meet growing market demands, packaging becomes one of the most important stages in the manufacturing process. This is where 25’s cigarette packer machines play a vital role. Designed specifically for high-volume operations, these machines help manufacturers achieve precision, productivity, and cost efficiency. Companies like Dynamic Tools are leading the way by offering industrial cigarette packaging solutions powered by smart automation for cigarette packaging machines.

Understanding 25’s Cigarette Packers

A 25’s packer is a specialized cigarette packaging machine that packs 25 cigarettes into a single pack instead of the traditional 20. This packaging format is popular in several global markets due to its perceived value and convenience. For manufacturers handling large-scale production, manually managing such volumes is impractical. Automated 25’s packers ensure that every pack meets quality standards while maintaining high output rates.

The Growing Need for High-Volume Packaging

High-volume cigarette production demands machines that can operate continuously with minimal downtime. Manual or semi-automatic systems often struggle to keep up with demand, leading to bottlenecks, inconsistencies, and higher labor costs. Best 25’s cigarette packer machines for high-volume production are engineered to handle these challenges by offering seamless integration with upstream and downstream processes such as cigarette making, wrapping, and cartoning.

Dynamic Tools understands these production pressures and designs machines that are robust, reliable, and optimized for industrial environments.

Smart Automation: The Backbone of Modern Packaging

One of the key advantages of modern 25’s packers is smart automation for cigarette packaging machines. Automation ensures that each step—feeding, aligning, packing, and sealing—is performed with precision. Sensors, programmable logic controllers (PLCs), and advanced control systems reduce human error and improve overall efficiency.

Smart automation also enables real-time monitoring of machine performance. Operators can quickly identify issues, adjust settings, and maintain optimal output without stopping production. This not only saves time but also significantly reduces material wastage, which is crucial in high-volume cigarette packaging.

Improved Productivity and Speed

Speed is a decisive factor in cigarette manufacturing. A well-designed 25’s packer can process thousands of packs per hour while maintaining consistent quality. Compared to older machines, modern packers from Dynamic Tools are built to deliver higher throughput without compromising accuracy.

With faster cycle times and automated changeovers, manufacturers can respond quickly to market demand, introduce new packaging formats, or scale production efficiently. This flexibility is essential in today’s competitive tobacco industry.

Consistency and Quality Assurance

Consistency in packaging directly impacts brand reputation. Uneven packs, damaged cigarettes, or improper sealing can lead to product rejection and financial loss. Industrial cigarette packaging solutions focus heavily on maintaining uniformity across every pack.

25’s packers are equipped with precision mechanisms that ensure correct cigarette count, proper alignment, and secure sealing. Automated inspection systems further enhance quality control by detecting defects before products leave the production line. This level of consistency helps manufacturers maintain trust with distributors and consumers alike.

Cost Efficiency in the Long Run

While investing in advanced packaging machinery may seem costly initially, the long-term benefits outweigh the expense. Automated 25’s packers reduce reliance on manual labor, lower operational errors, and minimize material waste. Over time, these factors lead to significant cost savings.

Dynamic Tools designs machines with durability and low maintenance in mind, ensuring a longer service life and reduced downtime. For manufacturers aiming to maximize return on investment, choosing the best 25’s cigarette packer machines for high-volume production is a strategic decision.

Seamless Integration with Existing Lines

Another major advantage of modern 25’s packers is their ability to integrate smoothly with existing cigarette manufacturing and packaging lines. Whether it’s upstream cigarette makers or downstream cartoning and wrapping machines, compatibility is essential for uninterrupted workflow.

Dynamic Tools specializes in providing industrial cigarette packaging solutions that can be customized based on production requirements. This ensures manufacturers can upgrade their packaging capabilities without overhauling their entire setup.

Supporting Sustainability and Compliance

With increasing focus on sustainability and regulatory compliance, packaging machines must meet strict standards. Automated 25’s packers help reduce waste by ensuring accurate material usage and minimizing rejected packs. Energy-efficient designs also contribute to lower power consumption.

Dynamic Tools keeps these factors in mind while designing machines, helping manufacturers align with industry regulations and environmental goals.

Why Choose Dynamic Tools?

Dynamic Tools has established itself as a trusted name in the tobacco machinery industry. With a strong focus on innovation, reliability, and customer support, the company delivers solutions tailored to modern manufacturing needs. Their expertise in smart automation for cigarette packaging machines ensures clients receive equipment that is future-ready and performance-driven.

From design and installation to after-sales support, Dynamic Tools partners with manufacturers to optimize productivity and packaging quality.

Conclusion

As cigarette production volumes continue to rise, the importance of efficient packaging solutions cannot be overstated. 25’s packers have become essential for manufacturers seeking speed, consistency, and cost efficiency. By leveraging smart automation, ensuring high-quality output, and integrating seamlessly into production lines, these machines redefine industrial packaging standards.